Pipeline machinery is essential for the oil & gas, carbon capture, water transportation industries, providing a safe and efficient way to transport resources over long distances. From padding machines to welding tractors, pipeline machinery can be used in a variety of applications.

It is important to understand the different types of pipeline equipment available so that you can choose the right type for your needs. Pipeline machinery includes side booms, welding tractors, padding machines, vacuum lifts, bending machines, crawler carriers and other equipment that are necessary for transporting materials through pipelines safely and efficiently.

By understanding this type of equipment, as well as how they interact with one another on the right of way, contractors can ensure their operations run smoothly at all times.

What Is Pipeline Machinery?

Pipeline machinery in construction is a specialized set of equipment used for the installation, maintenance and repair of pipelines. This type of machinery undertakes a variety of functions from digging the ditch, bending, welding, lowering in, and backfill.

It can also be outfitted with additional functions such as a variety of attachments for controlling water flow or chemicals to make sure the work proceeds smoothly and efficiently.

This equipment is invaluable when it comes to tackling labor intensive tasks, particularly those related to underground projects. With the right know-how and training, operators can use this machinery to carry out complicated tasks with ease, making it an essential tool when dealing with all kinds of pipeline construction jobs.

Why Is Pipeline Machinery Important?

Pipeline machinery is an important component of any pipeline installation project. It helps ensure a successful job and that the pipeline delivers its products safely and efficiently while also protecting it from damage caused by wear and tear for years to come. This type of machinery is responsible for the installation of millions of miles of pipelines across the United States and world.

Understanding the Different Types of Pipeline Machinery

Pipeline machinery is an important part of any pipeline project. This type of machinery includes a variety of asset classes including pipelayers, padding machines, welder tractors, crawler carriers and more. We will take a look at some of the most common types of pipeline machinery and their uses.

Pipelayers

Pipelayers are an important piece of construction equipment used for holding, lowering in, and connecting pipes. These machines feature a large counterweight and boom that positions and lowers in pipe on the right of way. All pipelayers are self-propelled, with rubber or steel tracks. This makes them easy to maneuver around the jobsite. Worldwide Machinery carries several pipelayer models with capacities from 40,000-200,000lbs. Pipelayers are also designed to work in a variety of terrains and can be used for various pipe-laying applications.

Pipeline Padding Machines

Pipeline padding machines (often called shading machines on renewable job sites) are essential in the backfill process to protect the pipe. These machines are used to precisely screen and fill the protective soil, or padding, material that goes around the pipes when they are buried underground. The padding helps protect the pipe from external forces, such as rocks or tree roots, which could lead to damage or breaks in the line. Pipeline Padding Machines feature wide tracks for navigating uneven terrain.

Welder Tractors

Welder tractors are specialized construction equipment used for welding steel pipelines and other large pipes. The tractor is an upfitted version of a dozer or crawler carrier and features a powerful engine, along with a knuckle boom, canopy, generator, and 4 Lincoln or Miller welders. As the name indicates, these tractors are designed for welding pipe on remote job sites and can handle challenging terrain.

Crawler Carriers

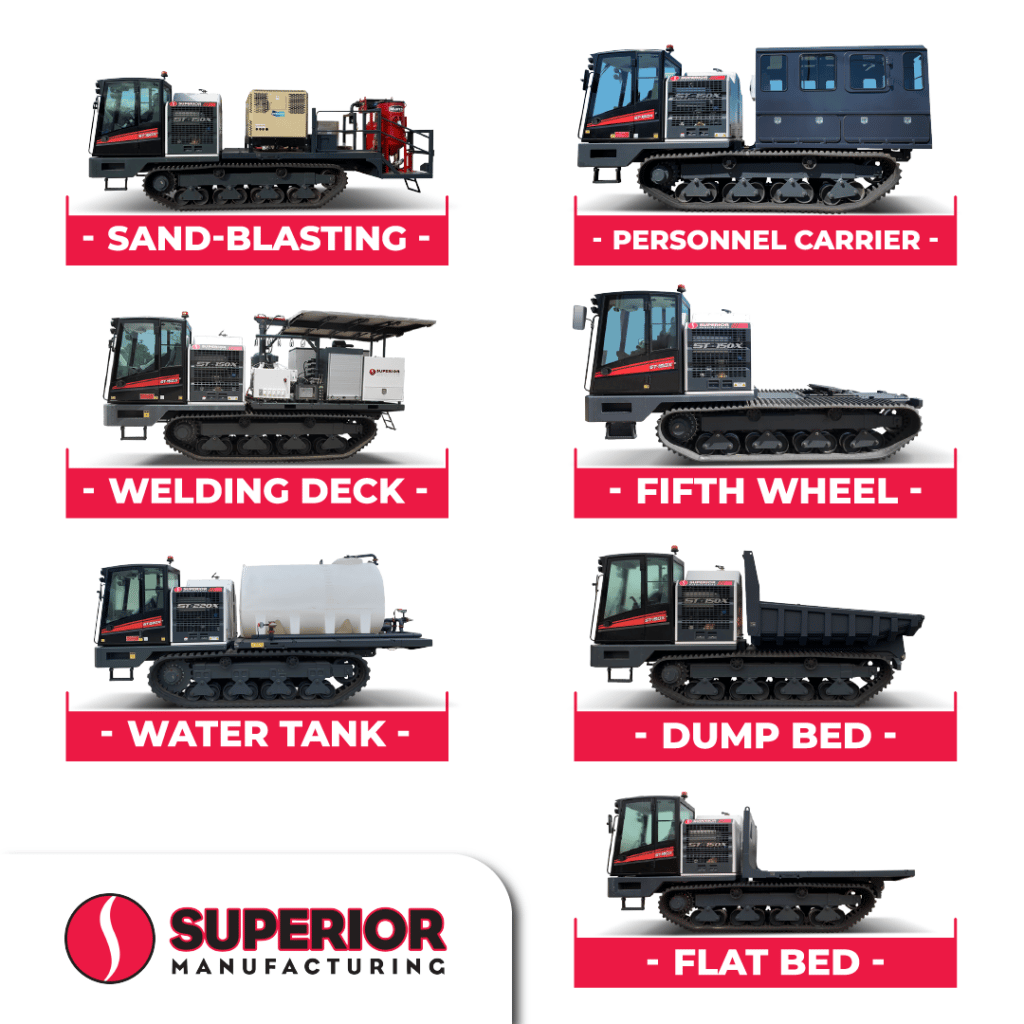

Crawler carriers are motorized vehicles that move on tracks instead of wheels. These machines are used for a variety of applications. Examples include hauling materials, transporting skids, sandblasting, welding, carrying personnel, water tankers, fuel/lube and more! They can also be used for hauling materials or equipment around a construction site. The tracks allow them to traverse uneven ground without getting stuck in soft soil or mud while still providing enough power to carry heavy loads over long distances.

Ditch Pumps

Portable ditch pumps are used to move water or other fluids from a ditch or excavation site to another location. Typical uses include when a pipeline needs to be installed in a location where water or other fluids are present. For example, a wetland or riverbed. By using a ditch pump to divert water away from the pipeline trench, construction crews can create a dry and safe work environment.

Vacuum Lifts

Vacuum lifts, also known as a pipe lifter, is a device used in pipeline construction to lift and move pipes on job sites. It is used for unloading and stringing pipe and can handle a variety of pipe sizes from 4” to 62”. Each vacuum lift includes a strong motor and sealed suction pad that creates enough suction force to hold the steel pipe while the excavator moves it into position.

Pipe Bending Machines

Pipe benders are used to bend pipes to the necessary shape or angle to match the terrain and ditch on the right of way. They come in a variety of sizes and can bend pipe from 6” to 60” through the use of different size bending shoes. They should be rented with an accompanying mandrel that fits on the inside of the bending pipe to avoid wrinkling or crimping.

Pipeline machinery is an essential component when it comes to laying the infrastructure on a given job site. There are many types of pipeline machinery available that can be used depending on the specific needs of your project. It’s important to research different types of pipeline machinery before making a decision so you can choose the one that best fits your needs and budget.

Benefits of Pipeline Machinery

In the oil and gas industry, pipeline machinery is a vital component for successful operations. Not only does it increase safety, but it also helps to improve performance, reduce costs, and increase efficiency. Let’s take a look at some of the benefits that come from using pipeline machinery in the oil and gas industry.

Increased Safety and Efficiency

Increased safety and efficiency are the most important benefits of using pipeline machinery on a construction job. By utilizing the latest equipment and technologies projects can be completed on time and on budget.

Improved Performance

Pipeline machinery also helps to improve performance in a number of ways. By having the right tool for the job, contractors can work more efficiently and accurately while reducing safety risks. To the end, it is not only important to choose the right equipment for your job but also the right equipment partner to work with. Working with the right pipeline machinery provider helps contractors reduce downtime and focus on other areas of their project knowing their equipment is in good hands.

Factors to Consider When Selecting Pipeline Machinery

There are several factors to take into consideration when it comes to buying pipeline machinery. Capacity and size, design requirements, and maintenance requirements are just a few of the considerations that need to be made when selecting the right pipeline machinery for your project. Let’s break down what you should look for in order to make an informed decision.

Capacity and Size

The capacity and size of the machinery you select will depend largely on the nature of your project. You want to make sure that the machinery can adequately handle the capacity of your pipes. This means taking into account not only their size but also their weight. If you’re dealing with larger pipes, you’ll need a machine with more power and strength than if you were dealing with smaller ones.

It’s also important to consider how often you plan on using the machinery. Purchasing may be the best option if the machine will be frequently in use. Alternatively, if the machine isn’t needed long term renting may be the best option.

Design Requirements

when making your selection you should also account for design specifications of the machine. Some machines are designed specifically for certain applications, while others, like crawler carriers, can handle multiple types of applications depending on their configurations. Make sure that whatever machine you choose has all the features necessary for your specific application.

Maintenance Requirements

Finally, another factor to consider when selecting pipeline machinery is its maintenance requirements. All machines require regular maintenance in order to keep them running properly and safely over time. This includes oil changes, cleaning filters, replacing parts, etc., so make sure you understand those costs when selecting a machine. If a machine requires special knowledge or software for maintenance and repair, make sure you know that as well.

Pipeline Machinery plays an important role in keeping pipelines operational and safe for use. From pipelayers to padding machines each asset has a specific purpose on the jobsite.

Whether you need equipment for new construction projects, rework, or tie-ins, understanding these various types of machinery will help you make informed decisions about your pipeline needs now and in the future. With this comprehensive guide in mind, we hope that finding the right pipeline machinery now feels less daunting.

Why You Should Rent or Buy From Worldwide Machinery

Whether you are in the oil and gas industry or you are simply looking for a reliable source of pipeline machinery, Worldwide Machinery is the answer. With a wide range of rental and purchasing options available, we have everything you need to get your project up and running. Let’s explore why renting or buying pipeline machinery from Worldwide Machinery is the right choice for you.

Rentals vs. Purchases

The first thing to consider when deciding whether to rent or purchase your pipeline machinery is the length of time that you will need it. If you only need the machinery for a short amount of time, renting is likely the best option, as it will be more cost-effective than buying outright. However, if you plan on using the machinery over an extended period of time, purchasing may be a better choice as it eliminates any monthly rental fees.

Quality Products and Services

No matter which option you choose (renting or buying), rest assured that all of Worldwide Machinery’s products and services are top-notch. We take pride in ensuring that all of our products meet industry standards and are built to last. In addition, we offer customer support so that any questions or concerns can be addressed quickly and efficiently.

Variety and Flexible Options

Worldwide Machinery has a wide selection of both new and used pipeline machinery, so there is sure to be something to fit your needs. Plus, we also offer a variety of rental assets so that you can tailor your equipment to meet your specific requirements without having to pay for a piece of equipment that is too big for what you need.When it comes to finding reliable sources for renting or buying pipeline machinery, Worldwide Machinery should be at the top of your list. With quality products and services, variety, flexible rental options, and customer support – not to mention competitive prices – there’s no reason not to give us a try. Get in touch with us today to find out how we can help with all your pipeline machinery needs.