Did you know that 25,000 kilometers of new pipelines are laid every year?

Pipelines are essential for transporting oil, gas, and other refined products. They transport these valuable liquids from the area of production to refineries and then to end-users.

This boosts economic growth along the production line and is the safest, most environmentally friendly way of transporting oil and gas.

However, pipelines are susceptible to damage from large rocks and debris during the backfill process and must be protected by screened material. For this you need a specialized padding machine.

This will extend your pipeline’s lifespan and specific material screening sizes are often required by the owner companies.

No contractor or pipeline owner wants to carry out expensive repairs if anything goes wrong when backfilling the pipeline. Using the right padding machine will ensure that you carry out the project perfectly and that your client is happy. This can lead to more projects in the future.

In this article, we look at how you can rent a pipeline padding machine—and some of your options.

Why Do You Need a Pipeline Padding Machine?

The planning and building of an oil or gas pipeline can take years. Choosing suitable locations and getting permission for the pipeline to run through certain lands is no small feat.

You need to make a plan to address the impact on the local community and the environment and get multiple permits.

The construction process is lengthy and complex. But one of the most critical steps is the final padding of the trench and coverage of the pipe after the pipe is laid. It is a pivotal method to protect the vital pipeline.

There are many ways that one can protect the pipe so that it lasts for decades. The average lifespan of a pipeline is around 50 years before you will replace it or it is abandoned.

The pipes are made of a special alloy, such as carbon steel or steel mixed with other metals. The walls of the pipe are thick to prevent pipeline failures. Corrosion, defects, and equipment failure can be catastrophic to the environment.

Over time, as the earth around the pipe shifts and moves, large rocks near the pipe can chip away at the material. This is a major cause of corrosion, especially in rocky areas.

Padding the pipeline is soft soil, placed in the trench before installing the pipe. You will also add this soft earth on top of the pipe before you backfill with the original topsoil and subsoil.

If you are constructing in a rocky area and want to add an extra layer of protection for the pipe coating, you will need a padding machine.

This machine takes the excavated soil from along the trench and sifts out the more rigid materials such as rocks or clay that can damage the pipe. It leaves a layer of fine, sifted soil covering the pipe.

Why Rent a Pipeline Padding Machine?

So, your pipeline trench has been dug, and it is time to lay down the pipe.

At this point, you are getting ready to pad the pipeline. You might find yourself wondering whether it is best to buy or rent a pipeline padding machine. There are advantages and disadvantages to both options.

Pros of Buying a Padding Machine

If you buy one or more padding machines, you will know that you have the machines at hand when you need them.

This is especially useful if your project is moving faster or slower than expected, and you want to ensure you have the machine on the correct days. Construction delays can be expensive.

Sometimes, buying large equipment like padding machines can give you tax benefits.

If you already own a padding machine, you can always rent extra from a padding machine rental company when needed.

Cons of Buying a Padding Machine

A pipeline padding machine can be expensive to maintain. It may also not be something you regularly need in your construction business.

Sizeable mechanical equipment like this works very hard on a pipeline construction site. If you own it, you are responsible for the repairs, replacing parts, and any breakdowns that may happen.

Different padding machines are suitable for various projects. For example, on a significant project, you might need several large padding machines which can sift through massive piles of excavated soil in a single day.

On a different project, you may need one small machine for the bedding layer of fine soil and a larger one to cover it. Alternatively, a short pipeline project may only require one small machine.

Therefore, unless you can own and maintain an entire fleet, renting will probably be better to adapt to the project you are on.

Pros of Renting a Padding Machine

When you rent a pipeline padding machine, you get to choose the best brand on the market. This ensures you get reliable and productive machines.

You can rest easy knowing the machinery is well maintained. The expensive costs of keeping the machines running are not your problem.

If anything goes wrong, the rental company will be there to help you sort it out while ensuring construction moves forward.

You can choose the right vehicle to fit your project. You will also have more flexibility and can make adjustments as your construction project advances.

If you are set on buying, renting can be an excellent way to try out the machine you want before committing a large sum of money.

Cons of Renting Padding Machines

There are few downsides to deciding to rent a pipeline padding machine. Rental will give you the greatest control over the project at hand.

However, you will need to plan to ensure the necessary equipment is available on the dates you wish to hire it.

Pipeline Padding Machine Rental Near Me

You might be wondering where you can rent a suitable padding machine. Of course, this will depend first on where your pipeline construction is.

The best choice is a company like Worldwide Machinery, which has a global presence. If you are in the United States, you can find rental locations in the following cities:

- Albuquerque, New Mexico

- Dallas/Fort Worth, Texas

- Denver, Colorado

- Dickinson, North Dakota

- Grand Junction, Colorado

- Lubbock, Texas

- Houston, Texas

- Las Vegas, Nevada

- Martin’s Ferry, Ohio

- Salt Lake City, Utah

For clients across the world, there are locations in:

- Monterrey, Mexico

- Dortmund, Germany

- Sydney, Australia

- Lima, Peru

- Parma, Italy

Are you somewhere else and still Googling “padding machine near me”? We also have direct representation in Russia, India, and China.

How Do You Rent a Pipeline Padding Machine?

Renting a padding machine for your oil and gas pipeline project is not complex.

You will need to have all the relevant details about the project at hand. This includes the dates for which you want to rent the heavy equipment, pipeline location, type of material, pipe size, ditch size, and required amount of padding.

If you are unsure which kind of padding machine you will require, you can rely on expert advice from your rental provider. They will help you decide what horsepower and screening area size you need for your project.

If you already know what machine you wish to hire, you can fill out a quote request and choose the model and make it. You will then select the rental period. This can be for several weeks or many months.

Your provider of choice will also ask you to include the location of the job. At this point, you will be asked whether you want the machinery transported to you.

You will also need to include your contact information. This will allow your equipment rental agency to reach out to you to finalize the hiring process.

How Is Machine Damage Handled?

In the construction industry, heavy equipment goes through a lot. This can lead to damage and wear and tear to the machine.

Because Worldwide Machinery supplies our own operator for SPD-250, SPD-350, and SPD-450 sized machines, customers are not responsible for any damages.

When renting a smaller sized pipeline padding machine (the SPD-150 and SPD-160), there will be a video check-in and video check-out process.

This means the Worldwide will not hold you responsible for any damage done before you rent the machine. And, it will simplify the discussion about any problems if you are responsible for the damage. This protects both parties in the rental agreement and helps resolve disputes.

When you return the machine, there will be a thorough checklist. The company will take pictures and videos and will carefully document everything.

What Are My Options for Renting a Padding Machine?

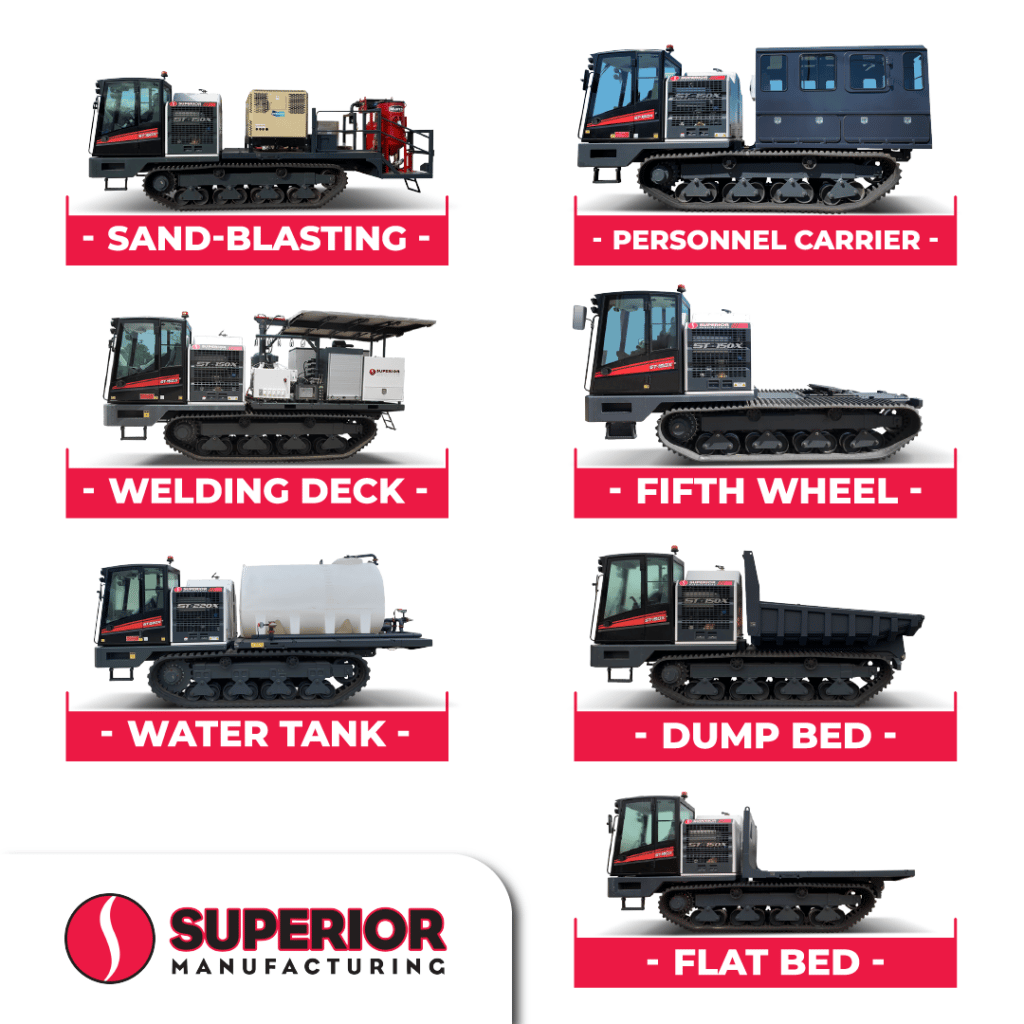

When renting a pipeline padding machine, you must choose from the following five options. They are all from Superior Manufacturing, which has been building specialized pipeline equipment for more than 30 years.

SPD-150

The SPD-150 is the smallest of our padding machines.. It is a remote control padder. It is ideal for:

- Minor projects and utility work

- Sites with restricted access

- Renewable energy jobs

Further specifications include:

- Horsepower: 140 HP

- Screening Area: 25 ft²

- Operating Weight: 26,455 lbs

This padding machine also has an escalator and screen sections that you can adjust depending on the soil material.

SPD-160

On some jobs, soil conditions make it difficult to carry out traditional front-loading feeding. This is where the SPD-160 comes in. It is a top-loading padding machine that is also remote-controlled.

It is ideal for tie-ins, small areas, or anywhere with more inconsistent material as the excavator operator can be more selective of the soil that gets top-loaded.

Further specifications include:

- Horsepower: 225 HP

- Screening Area: 57 ft²

- Operating Weight: 52,911 lbs

This padding machine works together with an excavator, feeding the dirt into the shaker.

SPD-250

If you are looking for a mid-sized padder that falls between the smaller utility machines and a larger pipeline padding machine for bigger jobs, the SPD-250 is a good bet.

This machine boasts:

- A folding conveyor

- An adjustable escalator

- A sliding cabin with duplicate controls

The SPD-250 is ideal for pipe sizes from 4 to 16 inches or project sites where transportation or permit rules have limited accessibility.

Further specifications include:

- Horsepower: 250 HP

- Screening Area: 30 ft²

- Operating Weight: 61,729 lbs

This padding machine is also a popular choice for renewable energy gigs.

SPD-350

The SPD-350 is our most popular padding machine. It has undergone multiple upgrades and is considered one of the most productive padding machines in the pipeline industry.

It is recommended for pipes that measure around 30 inches. It has a sliding and moveable cabin with duplicate controls on either side, an adjustable escalator, and a folding conveyor.

This machine also boasts three cameras to keep an eye on material loading. It also has a very stable undercarriage.

Further specifications include:

- Horsepower: 350 HP

- Screening Area: 60 ft²

- Operating Weight: 115,000 lbs

This padding machine does not need to be set up and is ready to go as soon as it arrives on the project site.

SPD-450

This machine is the largest that Superior makes and is perfect for major pipeline construction projects.

This model includes:

- A reversible conveyor for use on either side

- Duplicate control panels in the cabin

- An oscillating cabin to improve visibility

- An insulated engine to reduce noise

- An adjustable escalator

- Insulated cabin with AC/heater

- A spill pan vibrator to prevent sticking

Further specifications include:

- Horsepower: 440 HP

- Screening Area: 90 ft²

- Operating Weight: 118,500 lbs

The SPD-450 also boasts a conveyor dowel that you can adjust to suit the distance you need to place soil material back in the ditch.

Why Rent From Worldwide Machinery?

Worldwide Machinery has been in the business of selling and leasing heavy mining and construction equipment since 1949. As a family company, value, excellent service, and optimized productivity are extremely important.

So is offering a cost-effective service to allow you to carry out your project as smoothly as possible.

We have a fleet of more than 1,500 machines available. We have the latest models—you won’t find any old machines in our inventory! With deep experience worldwide, you will not find a better provider for your heavy equipment rental needs.

Our machines are maintained in tip-top condition, and our staff are friendly, knowledgeable, and always at your service.

On top of the latest pipeline padding machines, we rent tractors, trucks, dozers, and excavators to construction companies.

Pipeline Padding at your Fingertips

Building a pipeline is time-consuming and expensive, and a lot is at stake. The last thing you want is a mechanical breakdown or the wrong machine for the job.

If you are looking to rent a pipeline padding machine, Worldwide Machinery is your best choice. You can choose from an excellent range of vehicles and enjoy superb customer service.

Contact us to rent your next pipeline padding machine.